Are you continuing to use deteriorated equipment that was introduced 30 years ago while worrying about stoppages because, even though you really want to, you can’t replace the equipment as it is too difficult to suspend production? In addition, more users have a problem where they want to introduce the latest equipment but all the equipment would need to be upgraded to introduce the latest one.。

By taking advantage of our experience in equipment upgrade, Parker Engineering makes proposals that enable shortening of the work period, maintenance of the production system, and reduction of the space required in a complete upgrade or modification.

Need to upgrade equipment that has been in use for years

Do you have any problems like the following?

- There is a need to upgrade equipment,

but production cannot be suspended - There is hesitancy about upgrading equipment

because drawings are not available - Although work that requires a long work period was requested,

there is a need to shorten it

Two points of solutions

that only Parker Engineering can provide!

Shortening of production suspension period through unitization

Compatible with all kinds of equipment

For surface treatments that affect painting quality,

we can offer the highest quality

as the largest group in the surface treatment industry.

01.

Shortening of production suspension period

through unitization

We minimize the production suspension period by unitizing equipment and partially dismantling and partially replacing the equipment each time there are long consecutive holidays. Thus, we can reduce the burden on customers.

02.

Compatible with all kinds of equipment

Even for equipment whose manufacturer has already gone out of business or equipment with no available drawings, Parker Engineering offers the highest level of equipment by taking advantage of technologies we have cultivated until now, as well as by listening to what people in the field are saying.

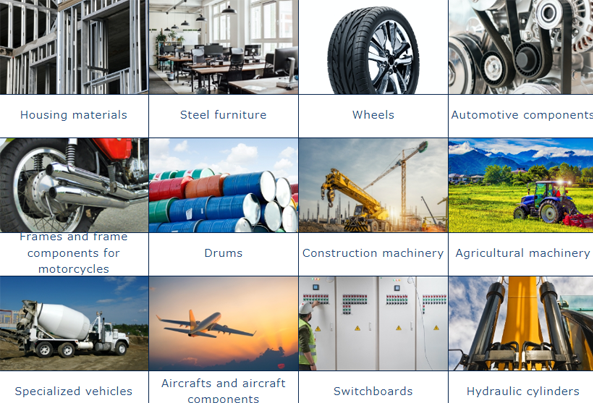

Steel frames for prefabricated houses

Steel frames for prefabricated houses Construction machinery

Construction machinery Agricultural machinery

Agricultural machinery Automobile lines

Automobile lines