In the modern age when the burden on the global environment is growing into a serious problem, it is the responsibility of companies to contribute to the realization of a sustainable society through taking a lot of energy-saving measures.

Energy-saving measures / Targeting reduction in the environmental burden

Parker Engineering offers equipment that reduces CO2 and VOC emissions to support the environmental friendliness of companies by utilizing our technologies and expertise that have been cultivated over the years.

Do you have any problems like the following?

- There is a need for saving energy

consumed by equipment - A reduction of equipment

running costs is under consideration - Environmental-friendly production is

requested from customers - There is a need for

utilizing waste heat and unused heat

Five points of solutions

that only Parker Engineering can provide!

Realization of energy-saving surface treatment

Increase in oven efficiency

Utilization of heat pumps

Utilization of waste heat and unused heat

Paint booth exhaust air

For surface treatments that affect painting quality,

we can offer the highest quality

as the largest group in the surface treatment industry.

01.

Realization of energy-saving surface treatment

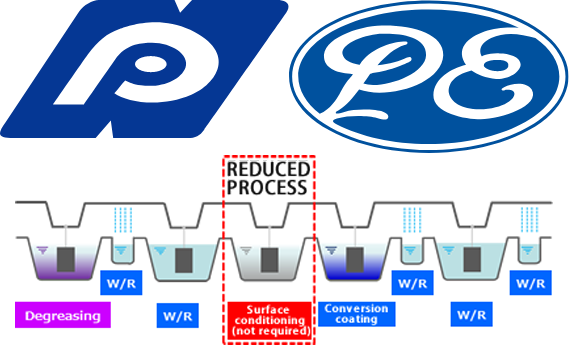

Through a cooperative system with Nihon Parkerizing Co., Ltd., we are fully prepared to offer new types of equipment that do not require surface conditioning. As the need for chemical agents and feed water used in the surface conditioning process is eliminated, this leads to shortening the line length and reducing wastewater treatment costs.

02.

Increase in oven efficiency

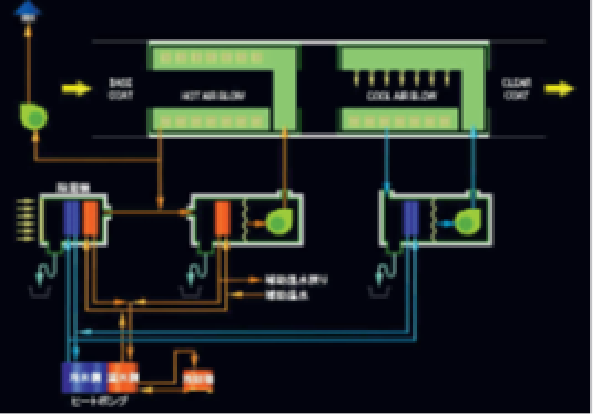

For ovens that consume the most energy in the painting process, we can propose a reduction of oven length through a design with increased heat shielding properties and temperature rise rate. This contributes to a reduction of CO2 emissions.

03.

Utilization of heat pumps

We can propose high energy-saving pretreatment systems, air charging systems, and flash-off through utilization of heat pumps.

04.

Utilization of waste heat and unused heat

Utilizing waste heat generated in RTOs (Regenerative Thermal Oxidizers ) and unused heat generated in each process contributes to the reduction of customers’ energy usage.

05.

Paint booth exhaust air

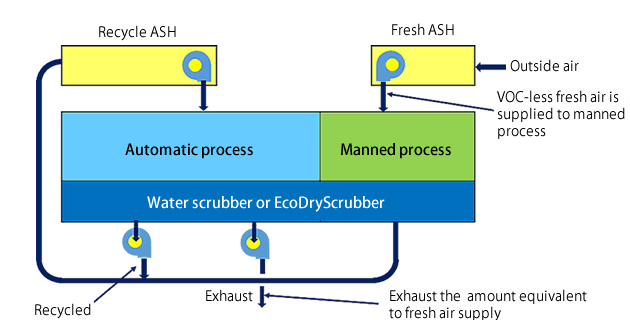

Recycling system

With an exhaust air recycling system in the paint booth, fresh air is supplied to manned processes, exhaust air is recycled to automated processes, and VOC emissions are reduced.

Parker Engineering can offer systems that can enhance recycling rate and save energy.

Steel frames for prefabricated houses

Steel frames for prefabricated houses Construction machinery

Construction machinery Agricultural machinery

Agricultural machinery Automobile lines

Automobile lines