STANDARD PRODUCTS

Standard products

Parker Engineering, with a deep understanding of painting work field, manufactures and sells standardized wet and dry type paint booths.

As they are assembled using panels and fans that are internally standardized, they can be delivered almost immediately. These are paint booths that can be assembled easily and are also very advantageous in terms of cost.

They can be compatible with a wide variety of applications, such as custom-order booths made by modifying standard booths and dust-resistant enclosures made by combining standard panels. In addition, we also propose Toreruzo, a product best for the separation and collection of forming and paint sludges.

Please also utilize our original filters and supplies best suited for each booth.

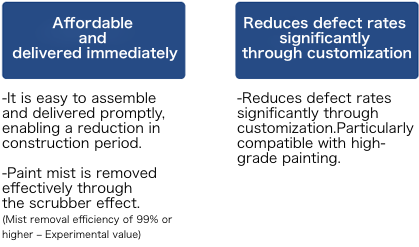

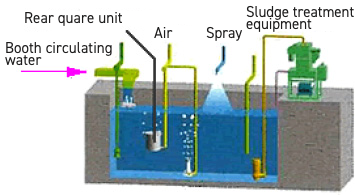

A wet-type local ventilation system that removes mist by utilizing the scrubber effect.

This system has the effect of achieving a mist removal efficiency of 99% (experimental value). As it is built using standard panels, it can be delivered promptly and at a low price. This enables a reduction in the construction period. In addition, it can also be particularly compatible with high-grade painting, such as resin painting, by adding special features.

Please also utilize the PBT (Parker Biotron) System that turns paint sludge into non-adhesive and decomposes it through biotechnology.

* The mist removal efficiency varies depending on the paint type, spraying method, and control conditions.

* To ensure proper performance, be sure to check the water level before operation.

■Parker Scrubber Booth (PSB)

Models employing highly corrosion-resistant ZAM material

・-Type P (with a water film plate)

・-Type PH (with a water film plate and a high opening)

・-Type E (pumpless type)

・-Type EH (pumpless type and with a high opening)

■Built-to-order booth

A paint booth that is best for high-grade painting such as resin painting

■Ancillary system

A system that treats paint sludge through biotechnology

According to customers’ needs, we offer a wide lineup of products such as a model with a high opening and a compact and easily portable model. We can also deliver customized products such as an accordion type.

As these products can be introduced with a short lead time and at low cost, a wide range of customers are satisfied with them.

-It is easy to assemble, delivered promptly, and enables a reduction in construction period.

-Harmful substances are directly absorbed to protect workers from solvents and paint mist.

-The low-noise type fan reduces noise inside and outside the booth.

A wide variety of models are available in accordance with needs and applications.

■Parker Paint Arrestor Booth

Parker Engineering offers a wide line up of various original air supply/exhaust filters according to painting purposes, supplies for paint sludge treatment systems (PBT systems) utilizing microorganisms, and pollution-free flocculating agents and additives to suit customers’ needs.

■Filters

The categories shown below are just for reference. As we propose optimum filters according to paint types and intended use, please feel free to contact our sales office in your area. Click here to find our offices| For air exhaust | |||||

|---|---|---|---|---|---|

|

-Arrestor pad | For general air exhaust Adaptivity to paints (high) |  |

-Neopad | For general air exhaust |

|

-Coolpad | For general air exhaust |  |

-Preroll filter half | For general air exhaust |

|

-Wave filter | For general air exhaust For large-scale booths |  |

-Neoroll filter | For air exhaust For primary air supply |

|

-Filter set | For air exhaust from paint booths | |||

| For air supply | |||||

|---|---|---|---|---|---|

|

-Parker air filter PS#4/PS#5 | For primary air supply For auto booths |  |

-Parker air filter PS#6 | For secondary air supply For auto booths |

|

-Parker air filter PS#8 | For secondary air supply |  |

-Three-pocket filter | For secondary air supply |

| For both air exhaust and supply | |||||

|---|---|---|---|---|---|

|

-Paint stopper | For secondary air exhaust For primary air supply |  |

-Double-pocket filter | For secondary air exhaust For secondary air supply |

■Supplies for wet type paint booths

|

-Supplies for PBT systems |  |

-Paint flocculating agents |

|

-Paint additives |

Effective separation and removal of paint, forming, and other sludges through vertical centrifuge separation

Parker Engineering offers our original vertical centrifugal separator that requires no filters, for separation and collection of paint and forming treatment sludges. It can be operated full-automatically and handled easily. In spite of its compact design, it reduces vibration and has superior durability.

It is applicable to the separation and collection of valuable resources such as silicon as well as sludge. It can also be modified at customers’ requests.

Product features

- It requires no consumables, and reduces running costs with its electric capacitance of 1.5 kW.

- It is vertical and produces superior centrifugal effects, leading to lower moisture content.

- It removes water completely to prevent dripping into the sediment receiver.

- Easy to handle with fully automated operation.

- It generates less vibration and low operation noise and is highly durable.

- It is equipped with an inverter whose conditions can be configured according to physical properties.

- It is compact in size and can be installed anywhere.

| Major specifications | Type I Aluminum rotor | Type II Stainless-steel rotor |

|---|---|---|

| Treating object | Paint sludge and industrial wastewater sludge and soil | Collection of valuable resources, forming sludge, corrosive sludge |

| Motor | 1.5kw2P/200V | |

| Rotor capacity | 5.5L | 4L |

| Effective capacity | 3 L | 2 L or more |

| Centrifugal effect | 3,000G | 5,000G |

| Maximum treatment capacity | 180L/min | 100L/min |

| Rotor material | Aluminum alloy | SUS304 |

| Wetted part material | SUS304 Aluminum alloy | SUS304 |

| External dimension of main unit[mm] | 500×830(including the operation board of 180 mm) x 810 high (excluding the mount) | |

| Weight | 200kg | 250kg |

| Option | |

|---|---|

| Safety control booth | Categories 2, 3, and 4 can be supported |

| Custom mount | A sludge receiver can be mounted, and scattering prevention measures, etc. can be taken |

| Inspection door with alarm | The safety measures for the inspection door are added |

| Door lock | The door is locked during operation |