Paint failures result from a complex mixture of various causes.

For example, the paint itself, surface treatment quality, paint/solvent properties, contamination of paint films/paints by dusts and seeds, control of temperature/humidity in the paint booth, temperature rise in oven, etc. could be a cause.

Need to enhance paint quality

Enhancing painting quality is an important task that leads to the elimination of waste in inspection and repair of paint defects, productivity improvement, and establishing product credibility.

Parker Engineering contributes to the enhancement of painting quality by taking advantage of our experience that has guided a lot of large-scale projects to success.

Do you have any problems like the following?

- Problem

with surface treatment - Contamination

by dust or seeds - Control of temperature/humidity

in paint booth - Mismatch between

paint and solvent - Temperature

rises in oven

Four solutions that only Parker Engineering can provide!

Improvement of surface treatment process

Countermeasures against dusts and seeds in the electrodeposition process

Countermeasures against the scattering of oversprayed paint in paint booths

Implementation of trial painting

For surface treatments that affect painting quality,

we can offer the highest quality

as the largest group in the surface treatment industry.

01.

Improvement of surface treatment process

Although surface treatment is an important process that affects painting quality, it is impossible to say it is free from problems.

パParker Engineering makes every effort to offer surface treatment equipment by taking advantage of our long years of experience and cooperation with Nihon Parkerizing.

02.

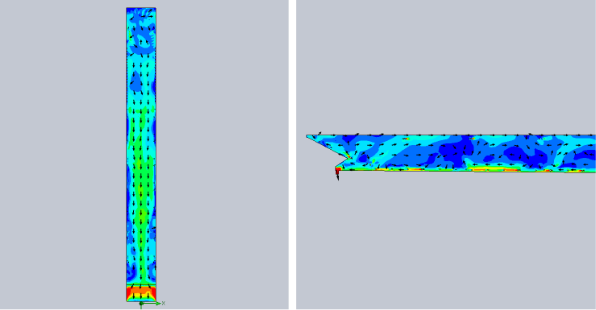

Countermeasures against dust and seeds in the electrodeposition process

During electrodeposition coating, dust, seeds, or bubbles may attach to paint surfaces depending on the conditions of agitation in tanks as well as of entry into or exit from the tank.

By visualizing the agitation condition in the inner tank of the tank through fluid analysis, we propose a design that prevents the accumulation of dusts and seeds.

03.

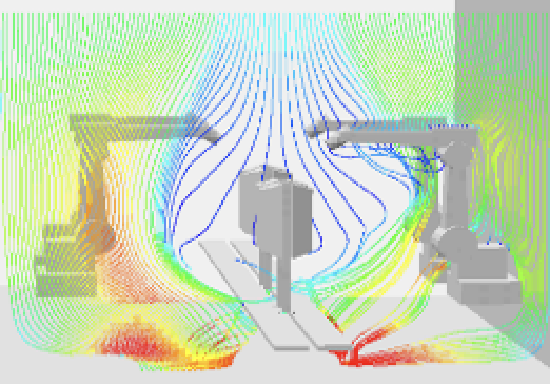

Countermeasures against the scattering of oversprayed paint in paint booths

Airflow control in the paint booth is an important key that determines painting quality.

Parker Engineering conducts the latest airflow analysis using 3D CAD to propose an optimum painting environment.

04.

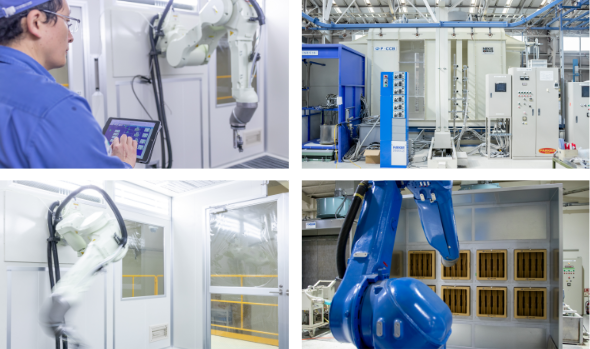

Implementation of trial painting

Painting requires fine adjustments under various conditions.

At our Technology Development Center, customers can try various conditions in the presence of our experienced engineers.

- -Verification using various types of paints such as powder, solvent, and water-based ones

- -Robots, reciprocators, and fixed/handy guns are available

- -Check of sludge treatment

Steel frames for prefabricated houses

Steel frames for prefabricated houses Construction machinery

Construction machinery Agricultural machinery

Agricultural machinery Automobile lines

Automobile lines