HISTORY

- Era of foundation -

Becomes the pioneer of the surface treatment industry in Japan.

■ 1950s -

1On February 24, 1951, the registration of a utility model patent for “a rust-preventing system using rust-preventive agents” that was applied for by President and CEO Yuji Satomi, the founder of our company, was granted by the Patent Office. Taking this opportunity, the Equipment Division was established in Nihon Parkerizing Co., Ltd. as a parent organization of our company to initiate the surface treatment system engineering business.

In 1952, the first system based on the Spra-bonderite method was delivered.

In 1953, by entering into a technology exchange relationship with Parker Rust-Proof Phosphating Company of America for the first time since the end of World War II and adopting its specifications, we started our activities as a pioneer of the surface treatment industry in Japan.

|

|

|

| President and CEO Yuji Satomi, the founder | The registration of a utility model patent for “a rust-preventing system using rust-preventive agents” was granted | The first system based on the Spra-Bonderite method |

- Era of technological development -

Supports industry with advanced technologies

■ 1960s -

In November 1960, we became independent of Nihon Parkerizing Co., Ltd. and established ourselves as Parker Sangyo Co., Ltd.

Around that time, the production of Spra-Bonderite systems for the light electric appliance and automobile industries became active and boomed.

1From around 1963, we started to deliver many surface treatment systems for both cut plates and coils to steel companies. In particular, for the purpose of activating steel plate surfaces, we developed a new fluidized bed coating method and played a role in enhancing the quality of precoated metals.

In 1965, the practical use of electrodeposition coating technology started. We quickly adopted this technology, delivering a large number of systems to the automobile and electronics industries, and also endeavored to develop a full immersion method.

Furthermore, the role we played in the cold forging field along with the advancement of technological innovation was also important. Using our umbrella type tact method/rabbit method , we achieved manpower reduction and automation of the bonderite-bonder lube method, which was patented by Nihon Parkerizing Co., Ltd. This method was adopted in many industries including the automotive parts industry and contributed to streamlining.

|

| Surface Treating Equipment of Coil & Sheet |

- Era of advancement -~

Becomes a comprehensive painting plant manufacturer.

■ 1970s -

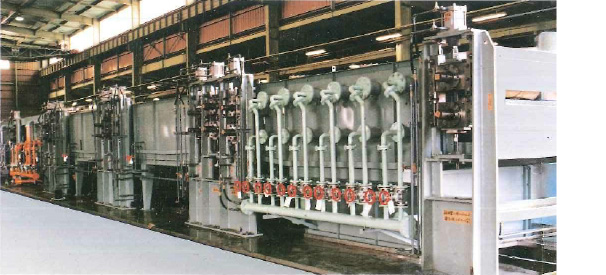

In 1974, in order to morph from our conventional business that was mainly focused on surface treatment systems into a comprehensive painting plant manufacturer, we entered into a basic technology partnership agreement with Otto Durr in West Germany to master integrated Western painting systems including the vertical full immersion method (Feiertag method) for automobile bodies, ED devices, ovens, and paint booths, etc., that they owned. As a result of continuing our own research and development to link this to the mass production method, this had a great influence on measures for reinforcing the prevention of rust on automobile bodies that became a problem in later years, and became a factor in taking the lead in the full dip method ahead of our competitors.

In the automobile industry where the export of passenger cars to the U.S. market was started for the first time in 1958, automobile exports increased year by year and Japanese cars started to be used all over the world. As a result, various problems that could not be expected previously started to occur. Among such problems, the biggest one was rust prevention capability. The modification of electrodeposition coating systems for cationization was started in 1978, and surface treatment systems were modified into the full dip type in 1979. By applying our own technologies that we had been in the process of developing, we could deliver many systems to meet customers’ demands.

On the other hand, Parker Arrestor Co., Ltd., that was later integrated with our company, was also founded in 1970. With the Painting System Division at the center, this company developed through the manufacturing and development of various types of air filters and related devices. It had engaged in the manufacture and sales of Arrestor dry paint booths since its foundation and had also succeeded in the domestic production of the Arrestor Pad in collaboration with Oji Paper Co., Ltd. in 1972. In 1975, it entered into a technology contract with Revage Co., Ltd. in the United States to start the manufacture and sales of Parker Scrubber Booths.

|

|

| Platecoil | Pretreatment Equipment(Full-Dip type) |

- Era of overseas expansion -

Establishes a global support system.

■ 1980s -

In November 1986, the company name was changed to Parker Engineering Co., Ltd. and the headquarters were relocated to Chuo Ward, Tokyo.

In the 1980s, the traditional concept of rust prevention coating focusing on practicality changed, and the trends toward qualitative improvement of paints expanded in pursuit of added value in various industries. As a result, the painting system industry became active.

On the other hand, however, the economic environment surrounding Japan became very severe, and it was the time for companies to establish production bases in foreign countries. As a result, the importance of our overseas business plan increased further.

Since we constructed a surface treatment and painting plant for automobiles and motorcycles in Thailand in 1965, we have dealt with many plants in Southeast Asia and Taiwan. Furthermore, we built many lines for automobile bodies and components in Eastern European countries and the Soviet Union in the 1970s and in the United States in the 1980s.

Since the 1990s, with an increase in orders for plants in Taiwan, Southeast Asia, and China, we established local corporations one after another to reinforce our sales capabilities and after-sales service.

In addition, for the promotion of overseas business, we quickly introduced a CAD system in the 1980s to establish a system that enabled us to promptly respond to the needs of domestic and foreign customers.

● History of establishment of our major overseas business bases

1987: Established PE OF AMERICA, INC. in Chicago, Illinois, the United States. Established TAIWAN PARKER ENGINEERING CO., LTD. in Taipei, Taiwan.

1988: Established PARKER ENGINEERING (THAILAND) CO., LTD. in Bangkok, the Kingdom of Thailand.

1995: Opened a liaison office in Shanghai, the People’s Republic of China.

1996: Established P.T. PARKER ENGINEERING INDONESIA in Jakarta, the Republic of Indonesia.

1997: Established PET TRADING CO., LTD. in Bangkok, the Kingdom of Thailand.

|

|

|

| Shanghai Office | Indonesia Office | Thailand Office |

- Era of continued expansion and extension -

Reinforces multi-layered technological and sales capabilities.

■ 2000s -

In 2000, we merged with Parker Arrestor Co., Ltd. that is also in the Nihon Parkerizing Group. That enabled us to reinforce the technological capabilities of the Painting Equipment Division and perform a wide range of sales activities, as a comprehensive painting and surface treatment equipment company.

The partnership with Durr that began with the business alliance in 2008 developed further in the form of capital and business alliances in 2011. Our relationship has been steadily reinforced through intaking orders for domestic and foreign projects jointly.

In addition, aiming to establish our technological capabilities, we reopened our “Adachi R&D Center” in 2016. It has become a research and development facility where various types of simulations of painting quality and booth performance can be performed.

In 2017, we integrated the ionics business of Nihon Parkerizing Co., Ltd. that is engaged in the development, manufacture, and sales of powder coating devices and equipment. In this way, we integrated the equipment and system businesses in our group to enhance customer satisfaction and services. In 2018, we refurbished the “Technology Development Center” that was used in the ionics business for further improvements.

In our overseas business, our sales grew approximately twice between 2000 and 2010, which led to rapid expansion of our business. In FY2010, we received orders for large-scale projects including surface treatment and painting lines for large-scale bus bodies/frames, one after another. In addition, we have been continuously receiving orders for full-turnkey projects for automobile body lines.

Based on the new technologies that we acquired through the merger, integration, and business alliances, we have been vigorously expanding our sales activities both domestically and internationally to this day. We will continue to lead the next-generation surface treatment industry by employing advanced technologies with environmental-friendliness and great originality.

|

|