Paint booth and air-conditioning system

In the paint shop, the booth is the most important equipment where the paint is applied to the job. The paint booth and the air supply unit consume approximately 60% of the energy in the entire paint shop. Therefore the performance of the equipment has a large effect on the quality and energy performance of the paint shop as a whole.

Parker Engineering provides the advanced equipment with drastic energy savings such as the latest waterborne 3C2B process and a recirculated air system with EcoDryScrubber, a technology for the dry separation of paint overspray.

- AIR CHASE

- Exhaust recycle system

- Heat pump

- Paint sludge recovery system

- PBT system (Parker BioTron system)

- Integrated spray & drying booth for large work

- ESS Paint Booth

- Dürr EcoDryScrubber

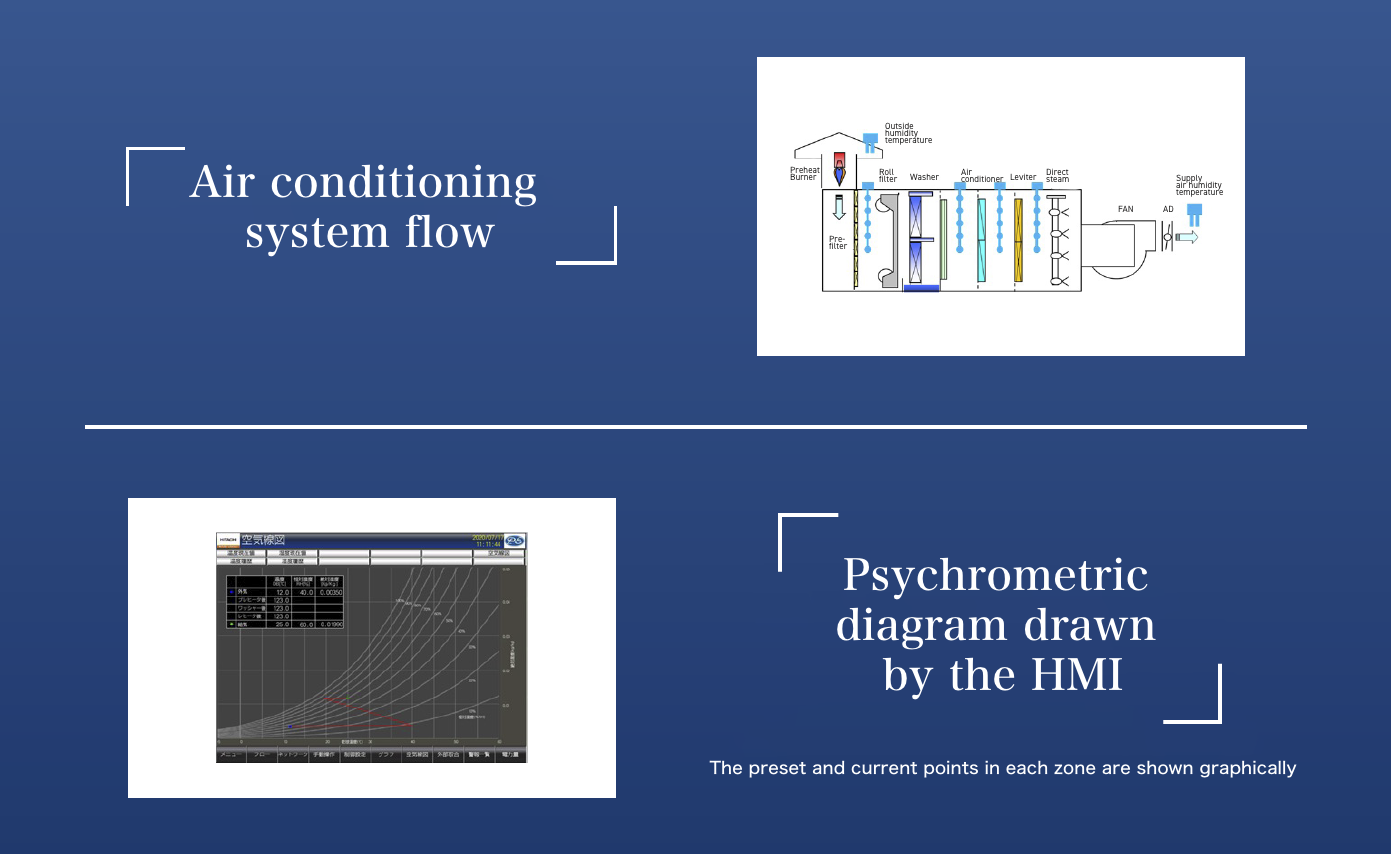

■AIR CHASE automatic air-conditioning control system

In conventional air-conditioning control, many regulators were employed to conduct air conditioning independently. However, as it was difficult to grasp the control points of individual zones, many controllers had to be used. As a result, that lead to an increase in cost.

Parker Engineering Co., Ltd. has realized easy-to-grasp air-conditioning by calculating our own control points with PLC and visualizing the air-conditioning points in each zone with HMI (Human Machine Interface).

■Advantages of the AIR CHASE

Reduction in the number of controllers

Initial investment costs can be reduced by decreasing the number of controllers, the amount of which had been large.

Visualization of air-conditioning by the HMI

Monitoring the graph through the HMI makes it possible to grasp the preset and current points just by looking and to comprehend air-conditioning control easily.

Reduction of the risk of controller failure

Minimizing the quantity of controllers enables a reduction of the risks associated with controller failures and safe operation of the air-conditioning system.

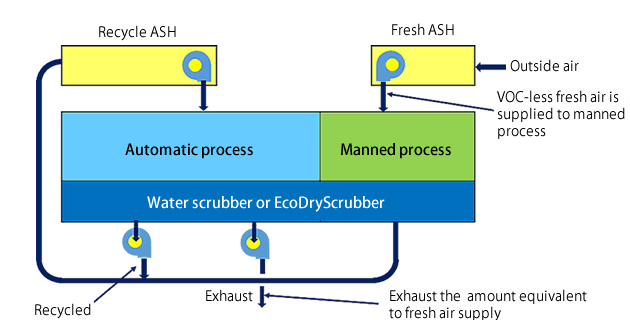

■Energy savings with air recycling

Fresh air is supplied to the manned process and the exhaust is recycled to the automatic process. We can offer various systems that improve the recycling rate.

Example of exhaust recycle

■Paint Booths / Paint applications / Ovens

Paint booths, paint applications and ovens are important processes to determine the surface qualities.

Parker Engineering provides optimized painting systems and the EcoDryScrubber for small paint booths to achieve energy savings and reduced environmental burden in cooperation with Dürr.

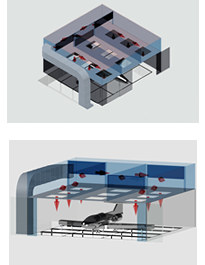

We can also supply a large booth which combines the function of paint applications and curing oven with high energy efficiency.

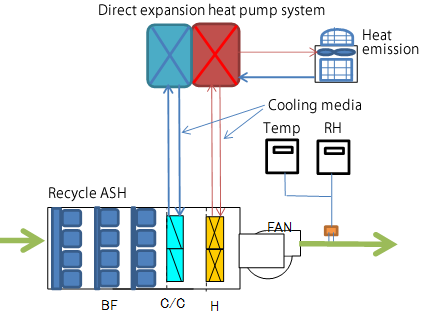

■Energy savings and reduced CO2 emission with the heat pump

The water-borne paint is increasingly used in the automotive industry recent years. After application of water-borne paint, the flash-off process, which required energy savings, follows. We can offer a very energy efficient equipment through the direct expansion type heat pump system (cooling media directly transferred to the heat exchanger) (Patent pending)

Use of heat pump in ordinary flash off

Example of direct expansion heat pump

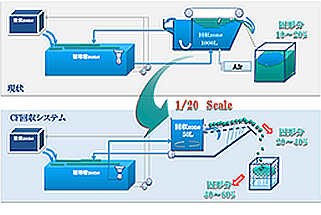

■Recovery system for floating/spreading paint sludge capable of water borne & solvent borne

A Parker Group company, Parker Corporation has developed CF agent (Crazy Flock), which offers the advantages of high speed condensation, high speed floating separation and high speed dehydration. Trials using your paint is possible at Matsubuse Plant of Parker Corporation.

■Instantly decompose sludge with contribution to the environment

PBT system (Parker BioTron system)

Since no chemicals are used, this system is not only environmentally friendly and safe, but also contributes to the reduced costs through less water consumption due to longer booth cleaning cycle, less sludge disposal, less operational labor and so on.

>More information about PBT system

■Special purpose vehicles and even airplanes can be painted!

■Reduced power consumption with recirculated supply air

ESS:Energy Saving System

This paint booth saves approximately 25% power consumption with recirculated supply air.

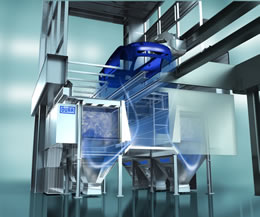

■The innovative overspray separation technology provides substantial energy savings and reduction of environmental burden.

EcoDryScrubber is an economically and ecologically efficient dry separation system. It achieves high efficiency through dry removal of paint overspray during the paint application process in connection with recirculating the spray booth process air.

Main features

Stable painting process opens the way for global response.

Re-circulation of spray booth process air is the key to a globally stable process, resulting in constant application quality. Whether running the plant in India – in 35℃ and extremely high humidity, or in Russia – in minus 20℃ and dry air, a stable temperature and humidity in the paint application process area can be held without effort. The small amount of conditioned fresh air makes the process practically climate independent. EcoDryScrubber saves resources, stabilizes the painting process and at the same lowers investment and costs per unit.

■Advantages of dry separation are now available in small booths

Dürr has developed a new EcoDryScrubber which can be installed for small paint booths, the working deck of which is near the factory floor level. Although the overspray intake of the existing EcoDryScrubber was located at the upper end of the hopper, that of the new EcoDryScrubber has been relocated to the right lateral side of the hopper. This design change has lowered the operational level of painting work significantly. Now, EcoDryScrubber can be used in the general painting industries as well as the automotive industry. A real booth for demonstration is available for your visit at the Dürr Technology Center Tokyo.