PARKER LEAPS

By adding IoT to advanced surface treatment and painting technologies

continuous enhancement of productivity is achieved.

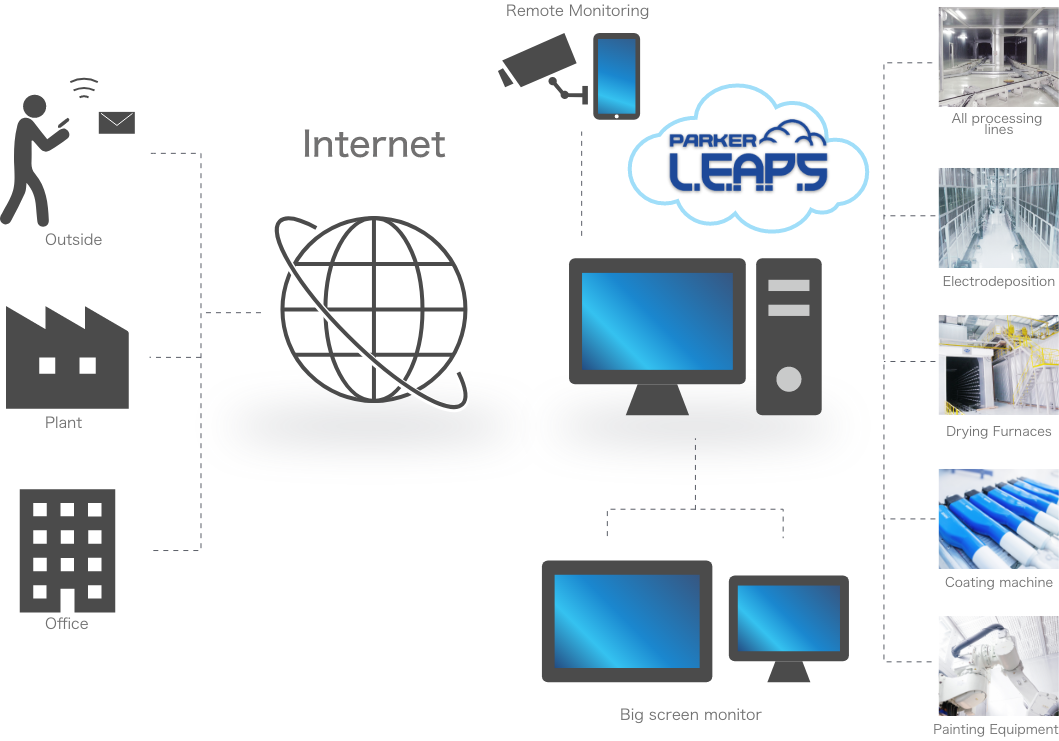

“PARKER LEAPS” is a tool that improves work efficiency by quantifying information such as production, quality, cost, environment, etc. to impart equipment conditions and issues in an intuitive manner. As it employs a highly secure cloud network, it makes it possible to check various information on equipment in real time with smart devices or tablets even remotely. In addition, based on the inspection information and maintenance history collected to the cloud, preventive equipment maintenance can be conducted efficiently.

※「LEAPS」… launcher for equipment information and problem solution