FOR AUTOMOTIVE INDUSTRIES

Pretreatment Equipment

For the pretreatment of painting, degreasing and phosphate coating on the metal surface are performed. Pretreatment enhances anti-rust and paint adhesion performance, and is so important process as it determines the final painting quality.

Parker Engineering can provide the next-generation revolutionary equipment in cooperation with Nihon Parkerizing, which is the core company of the Parker Group. We will offer an optimized process and will proceed the design following the concept that the energy consumption shall be minimized.

Conversion coating

System provision in cooperation with Nihon Parkerizing, chemical supplier

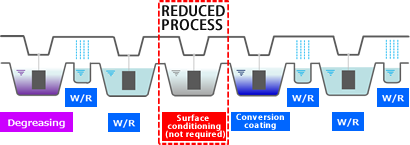

With full supports of Nihon Parkerizing, we provides the pretreatment equipment for the new conversion coating. Reduced equipment length and waste water treatment costs are brought through eliminating the surface conditioning process.

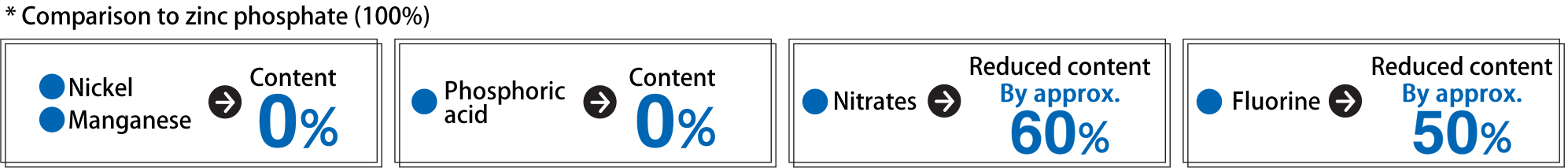

Next-generation coating chemical

Nihon Parkerizing offers “PALLUMINA” for automotive bodies and “PALLUCID” for other works.

The sludge generation is drastically reduced to lower than 1/10 compared to the conventional phosphating. Choking of nozzles and piping significantly reduces as well as the benefit of lowered operation costs and environmental burden.

The new chemical does not contain phosphorus, nickel and manganese therefore heavy metals have been reduced compared to the phosphating process.

Environmentally friendly pretreatment is realized according to strict effluent regulations.

Iron particle removal

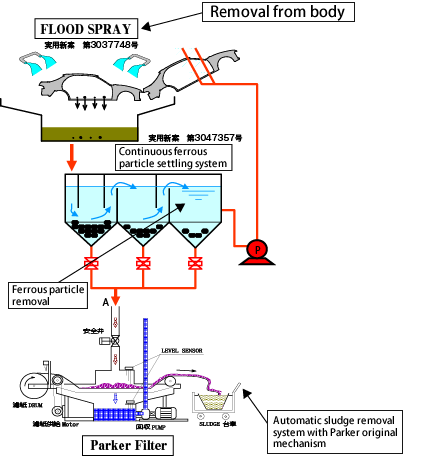

Elimination of foreign particles such as welding spatters that deteriorate finishing quality

Flood spray

Enhanced cleaning for bodies, which is more effective than purification of process water, brings high efficiency in reducing foreign particles.

Cyclone

It recovers ferrous particles through centrifugal elimination and sedimentation. The elimination rate is as highly efficient as up to 92% (reference from a production line).

An automatic periodical damping system realizes maintenance free and no consumable items.

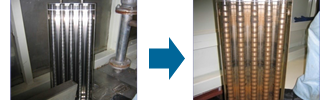

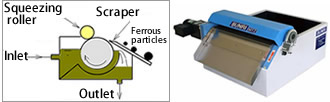

Magnetic elimination systems

for ferrous particles

Ferrous particle recovery systems using magnetic force are available.

Energy savings and lower operation costs are possible.

System with magnet bars

System with magnet bars

Magnet roller

Magnet roller

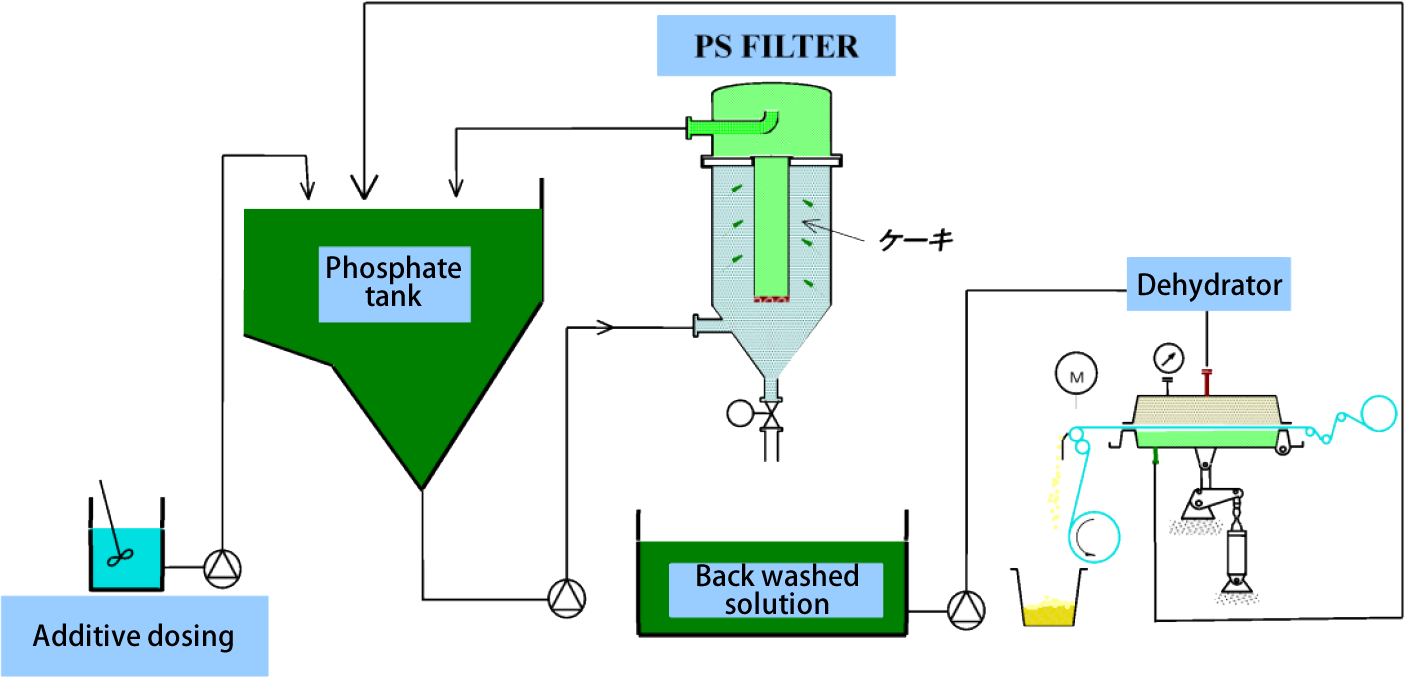

Sludge removal

Improved pretreatment quality through efficient phosphate sludge removal

PS filter( Phosphate sludge removal system )

- Adopting the whole bath filtration system, we have developed a system reducing the concentration of floating particles and being capable of both sinking sludge and floating sludge. Backwashing of the filter cloth can be done in a short time with compressed air. Nitric acid cleaning brings long lifetime of the filter cloth.

Full automatic paper filter

- This filtrating machine does following actions automatically – pressurized filtration, pneumatic dehydration, opening of chamber and discharge of cake. The machine can work as a dehydrator for purification and cake recovery.We can also provide the new type model capable of the next generation conversion coating.

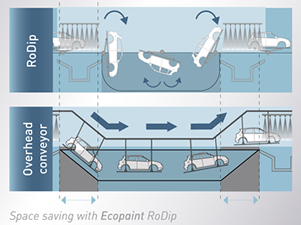

Dürr Ecopaint RoDip

Rotating paint system enhancing the productivity of the PT/ED process

The rotation of the complete body optimizes the process of immersion, flooding and draining.

The reduced plant length by Ecopaint RoDip utilizes the limited building rooms effectively and enhances the flexibility of layout.

|

|

|

Ecopaint RoDip M (Chain drive)

- The main characteristic of the Ecopaint RoDip M variant is the chain drive, on both sides, which pulls the rotation carrier through the Process line. Special V-cams guide the rotation of the rotating carrier through the tank.

Ecopaint RoDip E (Electrical drive)

- With Ecopaint RoDip E the car bodies are transported through the process by means of freely programmable, independently powered transport units. The unit has a conveying drive and a separate drive for rotation. The transport unit is positioned via a path measuring system. A WLAN signal is used to communicate with the controls.