FOR AUTOMOTIVE INDUSTRIES

Ovens

The oven cures the paint by curing process.

Parker Engineering can provide ovens in various types, such as various hot air discharge methods, different heating systems (direct / indirect / 1 burner system with incinerator), exhaust abatement systems(TO / RTO), tunnel configurations (camel back, flat) etc. This great variation enables us to offer an optimized system according to your budget, environmental regulations, restrictions of the building, etc.

A-type / Straight-through

Provide the best system according to the building restrictions and plant layout

A-type ovens

The most common system. The oven length is longer but it has characteristics listed below;

- Less heat loss from the entrance

- Power for air seal fan is not necessary

Straight-through ovens

Shorter oven length and lower oven height. Air seals suppress hot air leakage from the entrance. As for Dürr oven, the even shorter air seal zone length and even less hot air leakage will be achieved.

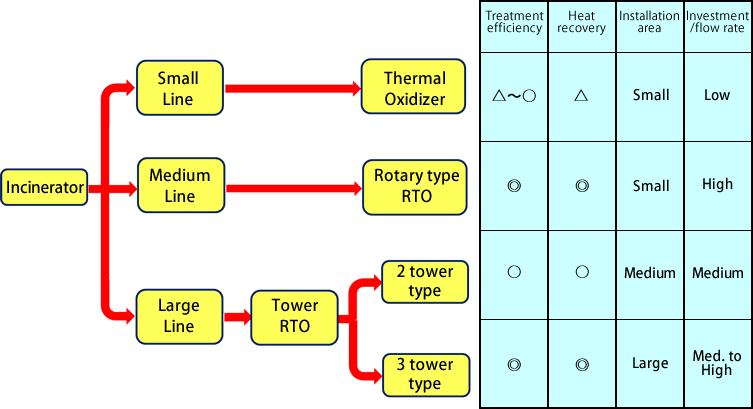

Incinerators

Able to select a suitable incinerator in proportion to the capacity of plant

Example of the incinerators of the oven exhaust

Able to select the system that matches each plant size.

Direct combustion incinerators

- Simple and high reliability

- Low investment

- Able to operate with one burner by controlling Heat exchange air volume.

- Able to achieve low running cost, by combing heat Recovery.

Tower type RTO

- High heat recovery rate: More than 95%

(depends on the volume of thermal storage medium) - High purification rate: More than 99%

(In case of tower type)

Dürr ovens

Compatibly achieve both quality and high efficiency, by optimizing

heating/drying process after coating

Ecopaint Oven by Dürr

Know-how that supports high painting quality

The ideal quality will be obtained at all drying/curing stages.

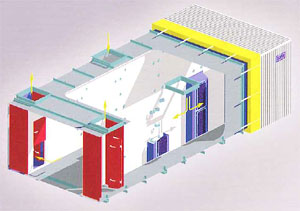

Modular built systems

Reduced environmental burden with higher energy efficiency

The energy efficiency has been drastically improved with enhanced insulation materials, heat recovery systems and evolutional air seal system, which halved the fresh air intake.

In addition, high performance solar energy collectors and combined heat & power units with a gas turbine are in Dürr’s vast line-up.