FOR AUTOMOTIVE INDUSTRIES

Paint Booth and Air Supply Unit

-

In the paint shop, the booth is the most important equipment where the paint is applied to the job. The paint booth and the air supply unit consume approximately 60% of the energy in the entire paint shop. Therefore the performance of the equipment has a large effect on the quality and energy performance of the paint shop as a whole.

Parker Engineering provides the advanced equipment with drastic energy savings such as the latest waterborne 3C2B process and a recirculated air system with EcoDryScrubber, a technology for the dry separation of paint overspray.

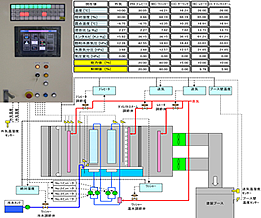

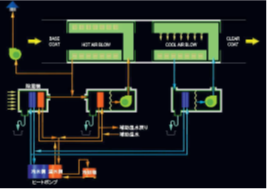

Air supply control system

Optimized booth air condition with processing according to outside air temperature & RH

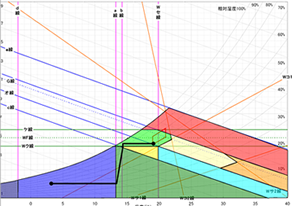

Air supply unit control system (Super Auto Turning System) is a feedback control system showing psychrometric chart.

|

|

Energy savings through zone controls of supply air temperature and humidity

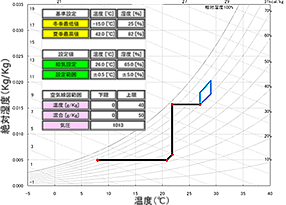

By setting a control range for the temperature and humidity, the system chooses the point which consumes the least energy for the outside air and it gives the minimum control.

| Season | Conventional pin-point setting | Conventional pin-point setting |

|---|---|---|

| Summer | 28℃±1℃ 75%±5% |

27℃ to 29℃ 70% to 80% |

| Winter | 20℃±1℃, 75%±5% |

19℃ to 21℃, 70% to 80% |

- [Current consumption monitor] steam, gas, CO2

- [Planned consumption monitor] steam, gas, CO2

Reduced costs through early maintenance point findings

Showing the actual operation of devices in the air supply unit and ideal control graph on the monitor simultaneously, the maintenance timing is found at an early stage through the difference, which brings reduced costs.

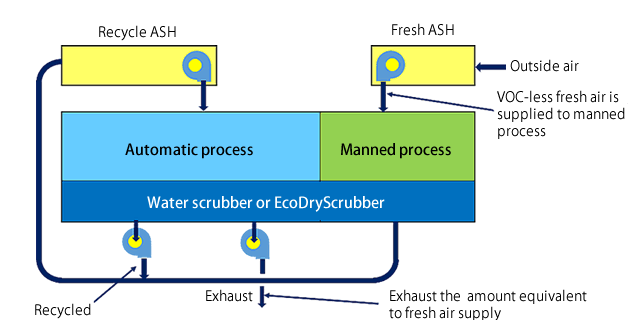

Exhaust recycle system

Energy savings with air recycling

Fresh air is supplied to the manned process and the exhaust is recycled to the automatic process. We can offer various systems that improve the recycling rate.

Example of exhaust recycle

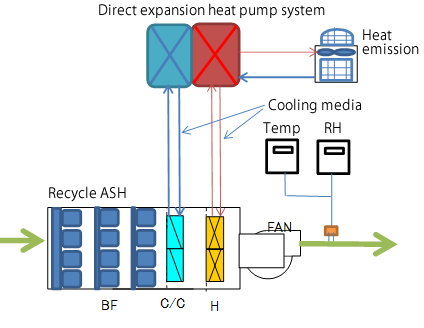

Heat pump

Energy savings and reduced CO2 emission with the heat pump

The water-borne paint is increasingly used in the automotive industry recent years. After application of water-borne paint, the flash-off process, which required energy savings, follows. We can offer a very energy efficient equipment through the direct expansion type heat pump system (cooling media directly transferred to the heat exchanger) (Patent pending)

Example of direct expansion heat pump

Use of heat pump in ordinary flash off

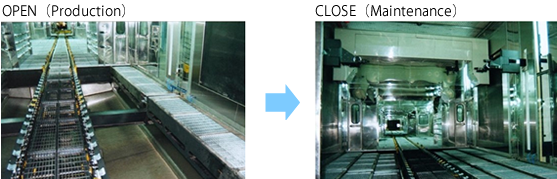

Automatic retractable grating

When the production is ongoing, gratings are stored at the edge of the spray room to prevent the overspray from adhering to the gratings.

When the production is stopped (maintenance) the gratings are extended towards the center for the convenience of the maintenance.

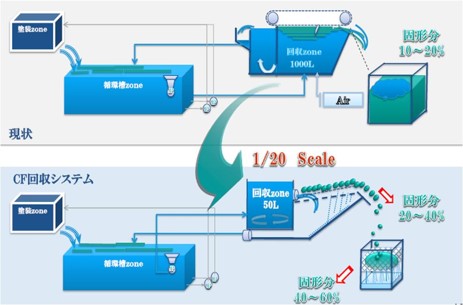

Paint sludge Recovery system

Recovery system for floating/spreading paint sludge capable of water borne & solvent borne

We propose a paint sludge recovery system with chemical as a measure to extend the lifespan of circulation water of the water scrubber booth.

We design the booth according to the custom-made chemical and can propose an optimized equipment for your production line.

A Parker Group company, Parker Corporation has developed CF agent (Crazy Flock), which offers the advantages of high speed condensation, high speed floating separation and high speed dehydration. Trials using your paint is possible at Matsubuse Plant of Parker Corporation.

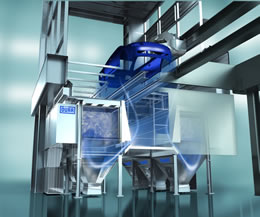

Dürr EcoDryScrubber

The innovative overspray separation technology provides substantial

energy savings and reduction of environmental burden.

EcoDryScrubber is an economically and ecologically efficient dry separation system. It achieves high efficiency through dry removal of paint overspray during the paint application process in connection with recirculating the spray booth process air.

Main features

Stable painting process opens the way for global response.

Re-circulation of spray booth process air is the key to a globally stable process, resulting in constant application quality. Whether running the plant in India - in 35℃ and extremely high humidity, or in Russia - in minus 20℃ and dry air, a stable temperature and humidity in the paint application process area can be held without effort. The small amount of conditioned fresh air makes the process practically climate independent.

EcoDryScrubber saves resources, stabilizes the painting process and at the same lowers investment and costs per unit.