IONICS

IONICS (Powder coating machine group)

Parker Engineering offers Pulse Power 9000 series of electrostatic powder coating equipment that were made by evolving our unique Pulse Power technology, as PARKER IONICS brand.

Compared to conventional products, the products of this series achieve higher coating efficiency, and the manual gun is designed to reduce fatigue even in long hours of operation.

In the construction of coating systems, they also enable high-speed color change and infinite colors.

In addition, connecting to the PARKER LEAPS also enables control of coating quality and preventive maintenance of equipment.

Furthermore, in addition to powder coating equipment, we also develop powder-related equipment.

- Manual gun systems

- Auto gun systems

- Powder coating booth

- Constant feeding systems

- New Device for Powders

■Manual Gun GX141Achieves both superior operability and enhanced functionality!

Characteristics

-450 g in weight – the lightest among our products

-Not only it is light in weight but also achieves good gravity center balance.

-The remote switch located on the back surface enables increase/decrease of discharge rate and air purge.

-An ion trap is available as an option. Effective in heavy film coating and enhancement of beautifulness.

-The gun cable is detachable.

Remote switch

■ Pulse Power 9000 S/TS (Twin Gun Type) Series Fuel Hopper Type Manual Guns

Easy to clean after use!

Characteristics

-The powder hopper capacity is 60 L, which can load a carton (15 kg) of powder.

-The round-shaped hopper enables easy disassembly and cleaning.

-Changeable to the twin gun type.

■Pulse Power 9000 B/TB (Twin Gun Type) Series Box Feed Type Manual Guns

Innovative box feed type!

Characteristics

-A powder box can be placed directly on this product to discharge powder using the vibration table and BF tube.

-As only the BF tube and injector need to be cleaned when changing powder colors, this product is suitable for small lots/color changes.

-Changeable to the twin gun type.

■Pulse Power 9000 K Agitation Hopper Model Coating can be performed even with a small amount of powder!

Characteristics

- Powder hopper capacity: 30 L

-As there is no need for powder flow, coating can be performed even with a small amount of powder, without using an air exhaust hose.

-As the angle of the agitation hopper can be changed during cleaning, color change can be conducted in a short time.

■Pulse Power 9000 CS Series Manual Guns for Laboratories Very easy-to-use Manual guns for laboratories!

Characteristics

-Powder cup capacities: 380 cc / 500 cc

-Best for use in preparation of coating samples.

-As the powder cup is self-supporting, the gun can be handled easily and suitable for prototyping.

■GX541 (Types A and B) Corona Charging Type Auto Guns Two types to choose from depending on the application!

Characteristics

-Type A is designed taking into consideration its cleanability at time of color change.

-Type B is compatible with special mounting, such as coating robots and fixed guns.

-Gun length: 350 mm

■GX532 Corona Charging Type Auto Gun A compact gun with an overall length of 225 mm!

Characteristics

-A short barrel gun that is best for mounting in narrow spaces.

-Also effective to use with coating robots.

■GX395 Digital Controller Equipped with advanced Pulse Power!

Characteristics

-The upgraded air circuit keeps comfortable powder discharge conditions from low to high volume range.

-The accuracy of total air volume management was also improved.

-The controller is equipped with evolved New Pulse Power.

The charging mode can be selected from among four types: Mode A, Mode B, Mode R, and continuous charging.

■Pulse Power 9000M Auto Gun Unit (Standard Model) High performance even in the basic model!

Characteristics

-Up to eight guns can be mounted.

-A basic type of auto gun unit.

-The powder hopper capacity is as large as 220 L.

-Adding a communication board becomes compatible with IoT.

-Adding a communication board becomes compatible with IoT.

■Pulse Power 9000M-JF/AF Auto Gun Unit (Constant Powder Feeding System)

Advanced unit incorporating our original technology!

Characteristics

-This model is equipped with our original technologies, which are a constant Powder feeding system that enables color change, “Just Feed,” and a screw type constant powder feeding system that achieves excellent powder feeding accuracy, “Ace Feed.”

-Connecting with “LEAPS” enables the monitoring of actually measured discharge amount relative to a preset discharge, which facilitates easy enhancement of film quality and traceability control.

-As the discharge amount can be controlled numerically (g/min), the management of coating conditions becomes easier, and it is also effective in reducing powder usage.

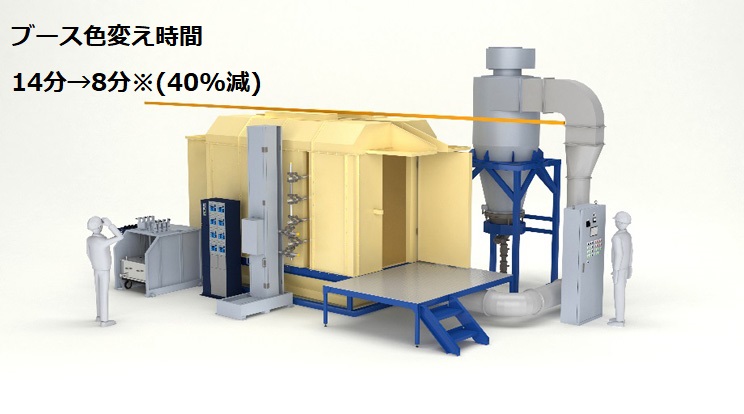

Color change booth

■Parker Color Change Booth (P-CCB)

■Quick Multi-Color Booth (Q-MCB)

■Compact Multi-Color Booth (C-MCB)

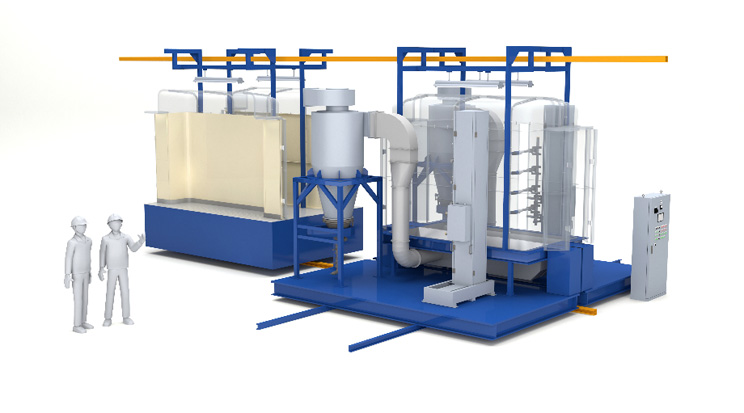

System

■“Twin Divide Multi-Color Booth System”: Patent pending

Compact Booth

■Compact Booth

Booth for Precoated Metals

■Precoated Metal (PCM) System

■Just Feed (JF) Constant Powder Feed System with Feedback Control Function

Just Feed is suitable for customers whose focus is color change performance!

An auto gun model equipped with Just Feed (JF)

M-JF Auto Gun

Characteristics

-This is an auto gun model created by equipping the Auto Gun M with the Just Feed (JF) with powder feed rate displaying and controlling functions.

-As it enables highly-reliable constant feeding, it exhibits tremendous power in film thickness management.

MBF [JF] Auto Gun

Characteristics

-This is a model created by equipping the MJF Auto Gun with the Box Feed.

-It is best for applications where frequent color changes and detailed film thickness management are required.

Major characteristics of the Just Feed

1. Precise constant feeding

-The feedback control function controls variable factors such as variation in powder level, wear of the powder contacting section, and adhesion of powder to the powder coating section to ensure an actual feed rate that is substantially identical to the preset rate.

2. High color change performance

-As the powder supplying device, sensors, etc., are cleaned automatically, multiple colors can be handled with only one supplying device.

3. Easy feeding rate check

-The capacitive sensor displays actual feeding rates digitally on a real time basis.

4. Integratable with existing powder supply devices

The JF can be docked with existing fluidized bed type feeders, regardless of manufacturers.

■Ace Feed (AF) Screw Type Constant Feeding System

Ace Feed is the first choice if long-term stable supply performance is the priority!

M-AF Auto Gun

Characteristics

-An auto gun model equipped with the Ace Feed (AF)

-A screw type constant feeding device that was developed to achieve free maintenance during long-term operation.

An auto gun model equipped with the Ace Feed (AF).

Powder is fed in a fixed quantity by controlling the rotation frequency of the screw.

Major characteristics of the Ace Feed

1. Precise constant feeding

Not affected by powder level fluctuations by employing a degassing system.

-Controlling the degassing volume prevents powder from jamming and flashing.

-The constant feeding performance during short-term On/Off operation is equivalent to that during continuous operation.

2. Simple structure

-The screw can be easily attached, detached, and cleaned.

-As the feeding rate measurement position is located at the feeder section, it can be measured with a single touch.

3. Not affected by the physical properties of powder

-This system is not affected by the particle size, particle size distribution, flowability, and specific gravity of powder.

4. Integratable with existing powder supply devices能

-The AF can be docked with existing fluidized bed type feeders, regardless of manufacturers.

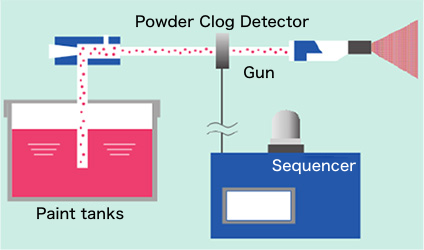

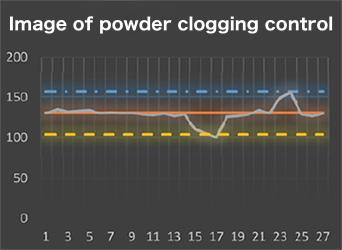

■Powder Jam Detector II Easy to measure and acquire data!

Characteristics

-The powder transfer condition is measured with the microwave method

-Compact in size and light in weight

-Alarms can be output by determining the condition where a powder transfer path is about to be clogged.

|

|

| Placing this product in the configuration as shown in the above figure enables the measurement of powder flow rate and digitalization of transfer amount. | Using the data that can be obtained using this powder jam detector enables various types of controls other than alarms. |

A contact form for the direct contact to the head office in Japan.

A request form for our company profile.

Overseas distributor

| South Korea | DUK AM SYSTEM 5, 1084 beon-gil, Gyeongin-ro, Bupyeong-gu, Incheon, 403-811, Korea Mr. B. J. Moon <Tel> +82-10-2568-4301 <FAX> +82-32-508-2208 |

|---|---|

| Thailand | >Parker Engineering (Thailand) Co., Ltd. 5th Floor, Thaniya Bldg. Room501, 510, 62 Silom Road, Suriyawongse, Bangrak, Bangkok 10500, Thailand Mr. Lawan Yodkham <Tel> +66-2-236-0120 <FAX> +66-2-236-0122 |

| China | Parker Engineering Co., Ltd. (Shanghai Office) Room 504-506, Gubei 1699 Plaza, No.1699 Gubei Road, Shanghai 201103, P.R.C. Mr. Haruhiko Miyazaki <Tel> +86-21-6270-3711 <FAX> +86-21-6270-5644 |

| China | Shanghai Hua Meng Machinery Enterprise Co., Ltd.(上海事務所) Rm. 1816, No. 16, Aly. 155, Xin yuam Road, Anting Town,Jiading District, Shanghai City, 201805 China Mr. M. L. Lin <Tel> +86-21-5959-2309 <FAX> +86-21-5959-2037 |

| China | SHANGHAI NOAH’S ARK AUTOTECK CO.,LTD. 568 Longpan Road, Jiading District, Shanghai 201801 P.R. China Mr. Kuo Yu Chung <Tel> +86-21-5990-0795 <FAX> +86-21-5990-03795 |

| Taiwan | Yarh Mong Mercantile Co., Ltd. No. 7, Lane 768, Wan-Shou Road, Sec. 2, Kuei-san Country, Tao-Yuan Hsien, Taiwan Mr. M. L. Lin <Tel> +886-3-329-7359 <FAX> +886-3-320-5164 |

| Vietnam | Tan Dai Thoi Co., Ltd. (TADACO Co., Ltd.) Hai Son Industrial Park, Duc Hoa Ha Ward, Duc Hoa District, Long An Province, Viet Nam Mr.Quach Le Huynh <Tel> +84-8-2451971+2541841 <FAX> +84-8-2542091 |

| Malaysia | Electro Powder Dynamics Sdn. Bhd. (EPD) No-11-B. 2nd Fl., Jalan MJ/7, Taman Maju Jaya, Batu 7, Jalan Klang Lame 46000 Petaling Jaya, Selangar Drul Ehsan, Malaysia Mr. Donny C. Koh <Tel> +60-3-7783-3092 <FAX> +60-3-7783-3091 |

| Indonesia | PT. PARKER ENGINEERING INDONESIA Perkantoran Hijau Arkadia, Tower F 6 Floor Suite 601 Jl. TB. Simatupang Kav. 88, Jakarta 12520, INDONESIA <Tel> +62-21-7884-8033 <FAX> >+62-21-7884-8030 |

| India | Parker Engineering (India) Pvt. Ltd. Unit No.9051 & 9052, 9th Floor, Vipul Square, B-Block, Sushant Lok, Phase-1, Gurgaon-122009, Haryana, India. <Tel> +91-124-411-2614, +91-124-411-2615 <FAX> +91-124-411-2613 |

| Philippines | PHILIPPINE PARKERIZING,INC. 1148 R.bernal St.,Rosario, Pasig City, 1609, Metro Manila, Philippines <Tel> +63-2-8571-1311 <FAX> +63-2-8641-3066 <MAIL> info@philparkerizing.com |

| Germany | SFB Service GmbH Daimlerstrasse 6, 71299 Wimsheim, Germany Mr. Kurt Wellmann <Tel> +49-7044-3044 <FAX> +49-7044-33488 |

|---|---|

| Italy | Cancellier Dino Srl. 33070 BRUGNEAR (Podenone) Viale Lino Zanussi, 1, Italy Mr. Cancellier Dino, President/Mr. Salvatore Falcone <Tel> +39-0434-616111 <FAX> +39-0434-616161 |

| Italy | Otek Consulting Di Luca Orland Via Don Angelo Arrigoni No 18, 24034 Cisano Bergamasco (Bergamo), Italy Mr. Luca Orlando, General Manager <Tel> +39-334 9069593 |

| Greece | N. & D. VAMVAKOUSSIS O.E. 36 XENOPOULOU Street, 16346 ILIOUPOLIS ‒ ATHENS, HELLAS Mr.George Vamvakoussis, President/Mr. Dimitris Vamvakoussis, (実務担当) <Tel> +30-210512-7764 <FAX> +30-210513-6518 |

| Spain | DISNAMAIR S.A. 28500 ARGANDA DEL REY Madrid, Spain Mr. Carlos Aguirre, General Manager & partner:/Mr. Alberto del Rio <Tel> +34-91-361-1051 <FAX> +34-91-361.01.09 |

| Poland | WMT Sp.zo.o. 63-100 SREM ul. STASZICA 1, Poland Mr. Lukomski (President) <Tel> +48-61-28-13215 <FAX> +48-61-28-13702 |

| Serbia Montenegro | Incop Line 11000 Belgrade, Promenska 2 (St.), Servia Mr. Ognjen Markovic <Tel/Fax> +381-11-3423-015 ; 3427-144 ; 2775-343 |

| UAE | INNOVATIVE METALLIC INDUSTRIES Emirates Modern Industrial Area, Umm Al Quwain, Behind Al Jabri Ready Mix, PB No. 3255 UAE Mr. Lal Joseph <Tel> +971-6-7672005 <FAX> +971-6-7664147 |

| Saudi Arabia | KUNOOZ TRADING Al Farazthaq Street, Riyadh 11491, Saudi Arabia Mr. Mohammad Abbas <Tel/Fax> +966-11-404-4399 |

| new zealand | Epac NZ Ltd. Unit 1 / 164 St Georges Road, Avondale, Auckland 0600, NEW ZEALAND Mr. Fialii Fui, Director/Ms. Annette Bertora <Tel> +64-9-8205481 <FAX> +64-9-8205484 |

| Australia | Epac Finishing Products Pty Ltd. Unit 10/99, Kurrajong Avenue, Mount Druitt, NSW 2770, Sydney, AUSTRALIA Mr. Darrel Abbott/Ms. Roslyn Furby <Tel> +61-2-9645-3900 <FAX> +61-2-9645-2514 |

| Canada、 United states of America、 Mexico |

Parker Engineering of Americo Co., Ltd. 38147 Abruzzi, Westland, MI 48185, USA Mr. John Cole, President <Tel> +1-734-326-7630 <FAX> +1-734-326-7638 |

|---|