FOR GENERAL INDUSTRIES

IONICS

Electrostatic Powder Coating Equipment Features

- Extremely safe, high performance electrostatic gun Exhibits good penetration and a high transfer efficiency with the new charge method ‘PULS POWER II’. Our gun is certified by the globally recognized FM Approvals in the US safety codes.

- Automatic control equipment for powder supply Optional automatic powder supply control equipment JUST FEED and ACE FEED can be mounted to eliminate excessive coating weight and realize a superior coating and reduced powder cost.

- Powder color change system Using the booth divide function, this system is optimal for lines which require frequent color changes on a par with solvent paints. The coating process is only interrupted for one minute, and we have realized a line operation ratio of 96%.

Product

Manual gun system

Extensive range of manual guns Choose from the digital GX8500 series or the analog GX7500 series.

GX132 Manual Gun

Features

- Mounted with Super Pulse Power which has 1.3 times of the electric charge of the conventional product.

- Outstanding penetration into the inside corners of box shaped work.

- Less powder accumulation on the inner floor of box shaped work.

- Less powder is blown away or lost even if the gun is moved close to the parts to be coated.

- The gun cable has connectors on both ends for one-touch replacement.

- Voltage impressed to gun tip is a maximum of 100Kv(standard polarity:negative)

- Weight: 480g

GX8500αS,GX7500S

- GX8500αS

- GX7500S

Features

- The powder tank can be disassembled for cleaning and reassembled easily without tools.

GX8500αB,GX7500B

- GX8500αB

- GX7500B

Features

- The whole powder box is vibrated with a vibrator in order to supplement the fluidizing of the powder by the BF tube, to ensure proper powder flow.

GX8500αCS,GX7500CS

- GX7500CS

- GX8500αCS

Features

- It consists of a cup type powder feed apparatus with a stand, a manual gun GX132 and a portable controller.

- It is optimal for creating coating samples and performing laboratory tests.

GX8500αC

GX8500αC

Features

- It consists of a small volume cup type powder feed apparatus mounted on the rear of the manual gun GX132B and a portable controller. It is optimal for creating coating samples and performing laboratory tests.

Automatic Gun

Automatic Gun GX8500A Series

GX531N Corona Charge Automatic Gun

- Original style change type.

- Mounted with Super Pulse Power

GX531T Tribo Charge Automatic Gun

- Realizes a high penetration and smooth paint film.

GX8500AM GX8500AM-BF

![[ Left ] Master Controller ,[ Right (top) ] 220L Hopper tank , [ Right (bottom) ] MBF](/wp-content/uploads/product/ms-plant/tosou-kansouro/ionix/gun/img08.jpg) [ Left ] Master Controller ,

[ Right (top) ] 220L Hopper tank , [ Right (bottom) ] MBF

[ Left ] Master Controller ,

[ Right (top) ] 220L Hopper tank , [ Right (bottom) ] MBFGX8500 βM

- This model is mounted with the standard automatic gun.

- For the powder feed equipment, choose either the apparatus for suctioning up powder from the tank top (photo) or suctioning from the tank side.

- The controller can be mounted up to ten guns. (photo shows 8 guns)

- This color change type automatic gun model has automatic cleaning apparatus mounted on the powder feed apparatus, and a box feed which feeds powder suctioned from the direct cartridge type tank (photo).

Automatic Gun GX7500 Series

GX531N Corona Charge Automatic Gun

- Original style change type.

- Mounted with Super Pulse Power

GX531T Tribo Charge Automatic Gun

- Realizes a high penetration and smooth paint film.

GX7500M GX7500M-BF

![[ Left ] Master Controller ,[ Right (top) ] 220L Hopper tank , [ Right (bottom) ] MBF](/wp-content/uploads/2017/03/img10.jpg) [ Left ] Master Controller ,

[ Right (top) ] 220L Hopper tank , [ Right (bottom) ] MBF

[ Left ] Master Controller ,

[ Right (top) ] 220L Hopper tank , [ Right (bottom) ] MBFGX8500 βM

- This model is mounted with the standard automatic gun.

- For the powder feed equipment, choose either the apparatus for suctioning up powder from the tank top (photo) or suctioning from the tank side.

- The controller can be mounted up to ten guns. (photo shows 8 guns)

- This color change type automatic gun model has automatic cleaning apparatus mounted on the powder feed apparatus, and a box feed which feeds powder suctioned from the direct cartridge type tank (photo).

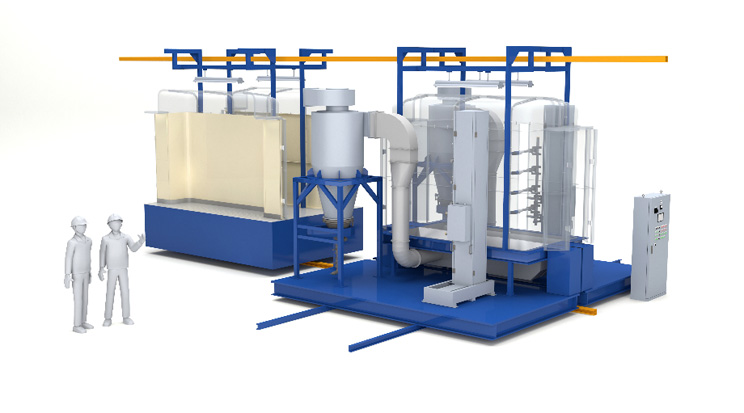

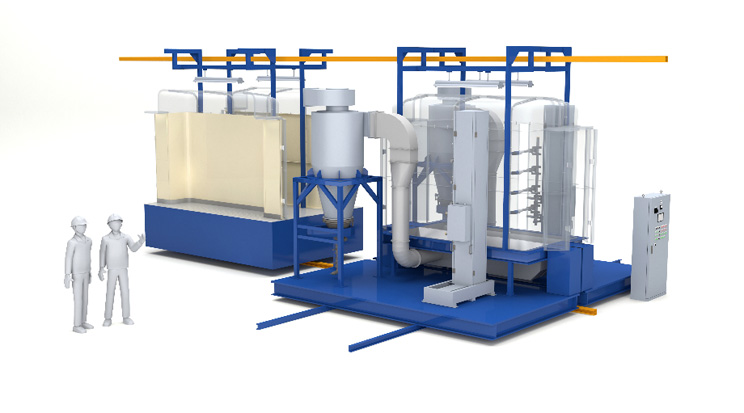

Powder coating Booth

We will meet your every need. !!

Parker Color Change Booth(P-CCB)

Color Change Time

14Min → 8Min※ (40%Reduction)| Work Piece Size | 1500H x 600W x 900Lmm |

|---|---|

| Auto Gun Qty | Total 6 Gun |

| Auto Machine | Reciprocator(2Sets) |

Feature1

- Powder coating booth wall is consist of special double plastic structure.

- Powder adhesion volume on the wall can be reduced by 50%.

Feature2

- Sequence air purge system on powder coating booth floor.

- Powder accumulation volume can be reduced significantly.

Quick・Multi Color Booth(Q-MCB)

Parker Color Chage Booth(P-CCB) can provide more cut down price than P-CCB.

- Air flow on Powder Coating Botth floor can prevent powder adhesion, Color change time can be made shortly.

- Simple and comapct construction suitable for multi color change system.

Running Situation of Powder Coating Booth

Compact Booth

Features of the compact booth

- It can be used with ease for creating samples and small lot work.

- It can be installed in a small space.

- This powder booth has a simple structure. The sides and roof are made of plastic panels, allowing for easy cleaning by hand with a simple air blow.

C-MCB(Compact-Multi Color Booth)

Features of C-MCB

- There is no limit to the number of colors and it can be used with any number of colors.

- The powder reclaim cyclone has a powder recovery efficiency of over 95%. A simple cleaning process completes the color change operation.

- The powder reclaim equipment is a pump type apparatus which uses a small volume of compressed air and recovered powder can be feed directly to the powder box or powder tank.

- Multi color powder feed apparatus (MBF=Multi Box Feed)is equipped with internal automatic cleaning equipment (jet nozzle) and can be used with any color by switching the powder box or powder tank.

- This powder booth has a simple structure. By manually cleaning with a simple air blow, the color change cleaning operation is complete.

PCM(Pre-Coated Metal)

Features of our PCM System

- Whereas conventional powder is applied on cast work, with our PCM system, the work is cast after the flat sheets or coils undergo pre treatment ,powder caoting and curing.

- The system makes high speed coating (5~30m/min.) possible, only a small space is required for installation, changing the color is simple and controlling the powder quantity is easy.

- Powder efficiency is high so it is also possible to build in a powder coating system without the reclaim process. Of course, a system which recovers and re-cycles the powder can also be incorporated.

- It is being utilized as a new powder system for refrigerators, washing machines, dryers, air conditioning compressors and other appliances.

“Twin Divide Multi-Color Booth System”: Patent Application

1. Features of the twin divide multi-color booth

- The two sets of DMCB installed in series on the line operate alternately.

- The DMCB which has finished painting is cleaned off-line and prepared with the next color powder.

- The time required for off-line cleaning of DMCB and color change is 15 minutes.

- This system is optimal for making the conversion from the current solvent lines to powder coating.

2. The booth which has finished painting can be moved off-line while painting continues on the line. “Divide Multi-Color Booth”

- The DMCB can be divided into left and right parts and moved off-line anytime during the continuous coating process.

- This system is labor saving as it is no longer necessary to take hangers on and off when changing color.

- The area enclosed after joining the cleaning booth and the booth which has finished painting can be cleaned by hand and the powder is reclaimed in the dust collector.

3. “Twin Divide Multi-Color Booth System” Lines implementing this system have an operating ratio on a par with conventional solvent paint lines.

- The interruption of painting during color change is approximately 40 seconds when the conveyor speed is 3m/min. or approximately 25 seconds when the conveyor speed is 5m/min.

- In order to prevent the parts to be coated at either end of the line from being coated with the next color or previous color used during the color change process, two meters of parts to be coated are removed, that is, one meter either side of the powder delivery point.

| Color change method | Coating interruption time per color change(min) | Color change frequency per 8Hr(time) | Down time per 8Hr(min) | Operating ratio % |

| Single C-MCB | 15 | 20 | 300 | 37 |

| Twin C-MCB | 3 | 20 | 60 | 87 |

| Twin D-MCB | 1 | 20 | 20 | 96 |

Fixed powder quantity feed system

JUST FEED ( JF )

Concerned about color changing? – JUST FEED is for you!

Electrostatic capacity type fixed feeding powder quantity and control system

![MBF[JF] for Automatic gun](/wp-content/uploads/product/ms-plant/tosou-kansouro/ionix/jf/img16.jpg)

M-JF for Automatic gun

- An Automatic gun system GX7000M equipped with Just Feed(JF),an automatic powder feed rate display & control system.

- With JustFeed a constant powder feed of high reliablity is possible,easing thickness control.

MBF[JF] for Automatic gun

- This model has the box feed mounted on the automatic gun MJF.

- Best suited for those applications that require frequent color change and precise thickness control.

![MBF[JF] for Automatic gun](/wp-content/uploads/product/ms-plant/tosou-kansouro/ionix/jf/img16.jpg)

Major features of JUST FEED

- Sure Constant Feed Feedback control function of JF compensates those disturbances to constant feed such as fluctuation of powder level in hopper, waering of parts or powder build-up on parts in feed system to secure actual powder feed rate as possible to desired value.

- Easy color change Powder feed system and sensor are of an automatic cleaning type, accommodating multiple color operation with a single feed system.

- Monitored Feed Rate Capacitance sensor(JF sensor) makes it possible to display real time and actual feed rate in digital display on Control Console.

- Applicable to Existing Electrostatic Equipment Just Feed can be used with existing electrostatic equipment having fluid.-bed/injection type powder feed system.

ACE FEED

Concerned about consistent powder feed in the long term ? Choose ACE FEED!

M-AF for Automatic gun

- Automatic gun model with ACE FEED(AF) mounted.

- Fluidized powder /air mixture is pumped by auger that is equipped into powder hopper. which was developed for maintenance-free long term operation

- Powder feed rate is controlled by the rpm of Auger driven by AF Motor. Control console incorporated in AF control panel controls the rpm of Auger.

Major features of ACE FEED

- Sure Constant Feed

- De-gassing device minimizes feed rate fluctuation.

- Powder clogging or flushing can be minimized by the control of de-gassing air volume.

- Powder feed aacuracy at frequent trigger on/off is equal to that at continuous operation.

- Simple structure

- Auger can be dismantled or attached from /to hopper with ease, making cleaning of Auger easy and quick.

- Actual powder feed rate can be caliblated near feed system, which makes calibration easier.

- Minimized influence of Characteristics of Powder Accuracy is little influenced by particle size,particle distribution,fluidability, or specific gravity of powder.

- Applicable to Existing Electrostatic Equipment ACE FEED can be used with existing electrostaic equipment having fluid.-bed/injection type powder feed system.

Enquiries

Please contact our sales offices listed below or a sales agent.

| Taiwan | Yarh Mong Mercantile Co., Ltd. No. 7, Lane 768, Wan-Shou Road, Sec. 2, Kuei-san Country, Tao-Yuan Hsien, Taiwan Mr. M. L. Lin <Tel> +886-3-329-7359 <FAX> +886-3-320-5164 |

|---|---|

| Republic of Korea | DUK AM SYSTEM 5, 1084 beon-gil, Gyeongin-ro, Bupyeong-gu, Incheon, 403-811, Korea Mr. B. J. Moon <Tel> +82-10-2568-4301 <FAX> +82-32-508-2208 |

| China | Shanghai Hua Meng Machinery Enterprise Co., Ltd.(上海事務所) 4879 Chao An Road, Huang du Town Jia Ding District, Shanghai City, China Mr. M. L. Lin <Tel> +86-21-5959-2309 <FAX> +86-21-5959-2037 |

| China | SHANGHAI NOAH’S ARK AUTOTECK CO.,LTD. 568 Longpan Road,Jiading District,Shanghai.P.R.China.201801 Mr. KUO YU CHUNG <Tel> +86-21-5990-0795*111 <FAX> +86-21-5990-3795 |

| Malaysia | Electro Powder Dynamics Sdn. Bhd. (EPD) No. 11-B.2nd Floor, Jalan MJ/7, Taman Maju Jaya, Batu 7, Jalan Klang Lama, 46000 Petaling Jaya Selangor Drul Ehsan, Malaysia Mr. Donny C. K. Koh <Tel> +60-3-7783-3092 <FAX> +60-3-7783-3091 |

| Thailand | Essom Co., Ltd. 510 Soi Taksin 22/1 Taksin Rd., Bukkalo Thonburi Bangkok 10600, Thailand Mr. Naris Srinilta <Tel> +66-2476-0034 <FAX> +66-2476-1500 |

| Vietnam | TADACO Manufacturing & Trading Co.,Ltd. Hai Son IP,Duc Hoa ward,Long An Province,VietNam Mr.Quach Le Huynh <Tel> +84-723.761.741/743 (Ext: 105) <FAX> +84-723.761.742 |

| New Zealand | EPAC NZ Ltd. Unit 7, 16-18 Taylors Road, Morningside, Auckland, New Zealand Attn: Mr. Fialii Fui <Tel> +64-9-846-6953 |

|---|---|

| Australia | Epac Production Ltd. 1B Melissa Street Auburn NSW 21444, Australia Mr. Des Field, President <Tel> +61-2-9645-3900 <FAX> +61-2-9645-2514 |

| Germany, Switzerland, Austria | SFB AG St. Dionysstrasse 31CH-8645 Jona, Switzerland Mr. Daniel Seiler, President <Tel> +41-5521-25423 <FAX> +41-5521-25422 |

|---|---|

| Germany | SFB Service Gmbh Boschstr. 7, D-71287 Weissach, Wurtt, Germany Mr. Kurt Wellmann <Tel> +49-7044-3044 <FAX> +49-7044-33488 |

| Italy | Italstatic Srl Via Della Stanga 2/b,23801 – Calolziocorte (Lecco),Italy Mr. Luca Orlando/General Manager <Tel> +39-0341-630473 <Tel> +39-0341-630589 <FAX> +39-0341-630200 <Mobile> +39-3488-133686 |

| Greece | Alcolor Ltd. 82, Lenorman Str., 104 44 Athens Greece Mr.George Vamvakoussis, President <Tel> +30-1512-7764 <FAX> +30-1513-6518 |

| Spain | DISNAMAIR S.A. Jose Picon 18, /28028 Madrid, Spain Mr. Carlos Aguirre, General Manager & partner: <Tel> +34-91- 361-1051 <FAX> +34-91- 361-0109 |

| Servia | Incop Line 11000 Belgrade, Promenska 2 (St.), Servia Mr. Ognjen Markovic <Tel> +381-11-3423-015 <FAX> +381-11-3427-144 |

| UAE | INNOVATIVE METALLIC INDUSTRIES Emirates Modern Industrial Area, Umm Al Quwain Behind Al Jabri Mix,PB NO3255 Attn: Mr. Lal Joseph <Tel> +971 6 7672005 <FAX> +971 6 7664147 |

| Russia | KAWAKAMI PARKER Prosspect Mira Ul., 74-1A-193, Moscow, 129041, Russia Mr. Tatsuya Kimura, Dupty Director <Tel> +7-95-933-8608 <FAX> +7-95-926-5159 |

| Egypt | Modern Coating (Union Coating and Chemical Industries) 9.520 Street, El Asafra Bahary, Alexandria, Egypt Mr. Bassem Maher <Tel> +20-35-53-3317 <FAX> +20-35-53-3317 |

| Canada, USA, Mexico | Parkwood Engineering Development Corp. (Parker Ionics Div.) 38147 Abruzzi, Westland, MI 48185, USA Mr. John Cole, President <Tel> +1-734-326-7630 <FAX> +1-734-326-7638 |

|---|